Colors

Order our color sample pack

NEW CONCRETE COLORS FOR 2026

Finishes

Custom Concrete Finishes: Exceptional & Durable

At 16JUIN, we pride ourselves on delivering custom concrete finishes crafted with 15 years of experience. We primarily utilize two foundational cement colors: white and grey. By adding high-quality pigments, we can produce an extensive range of vibrant and muted tones. Whether you desire bold hues or subtle shades, the result is determined by the precise pigment blend used in our concrete casting process.

Our concrete creations are uniquely cast within custom molds, ensuring that the chosen color is integrated throughout the entire piece—not just on the surface. This technique enhances the overall aesthetic and longevity of the products.

Once the concrete is cast, we allow it to harden before demolding it, marking the beginning of our intricate water polishing process. This method employs diamond pads to effectively remove surface imperfections, ensuring a smooth, refined finish.

In most cases, we expose the natural sand within the concrete mix, resulting in increased abrasion resistance and a stunning, authentic stone appearance. Exposed aggregate finishes are not only visually appealing but also durable, making them perfect for high-traffic areas.

While we can achieve a desirable “cream” finish, we advise against it for surfaces used for food preparation or dining, as this finish has lower abrasion resistance compared to our sand-exposed surfaces.

After the polishing process, we protect our creations with a top-quality protective layer. For detailed information, please refer to our Protection section (bottom of the page). Our finished pieces are soft to the touch and feature a semi-matte or matte finish in 90% of cases, ensuring both durability and aesthetic elegance.

Why Choose Our Concrete Finishes?

Customization: Tailored solutions to meet your specific design preferences and needs.

Durability: High-quality finishes designed to withstand daily use and maintain their beauty over time.

Expert Craftsmanship: Years of experience in the art of concrete design, providing you with stunning results.

Salt and Pepper

This is the most common finish. The surface appears neutral with minor imperfections. The surface is polished to expose the sand.

Suitable for furniture tabletops, countertops, integrated sinks.

Pressed/MARBLED

The pressed surface has more movement. The perfect imperfections give a more vibrant look to the piece. The surface is polished to expose the sand.

This two-stage casting technique allows to combine multiple concrete colours for specific projects. When casted with the same tone it brings a subtile and elegant feel to the objects. When casted with two opposite colours a more marbled look can be achieved.

Suitable for furniture tabletops, countertops, integrated sinks.

Tabletops at Lucy in the Sky // Restaurant in Helsinki

Drip Spray

The drip spray finish is made by spraying concrete to the surface at low pressure. The surface has a lot of movement and has a softer look than the pressed version. The surface is polished to expose the sand.

Suitable for furniture tabletops, countertops, integrated sinks

Trowelled

Trowelled surfaces are casted right side up. Once the concrete starts to set/ harden, the surface is flattened using trowels to achieve a dense and flat finish. The final surface has a lot of movement. The surface is then wet or dry polished to expose the sand.

Suitable for seamless projects and longer countertops, tabletops.

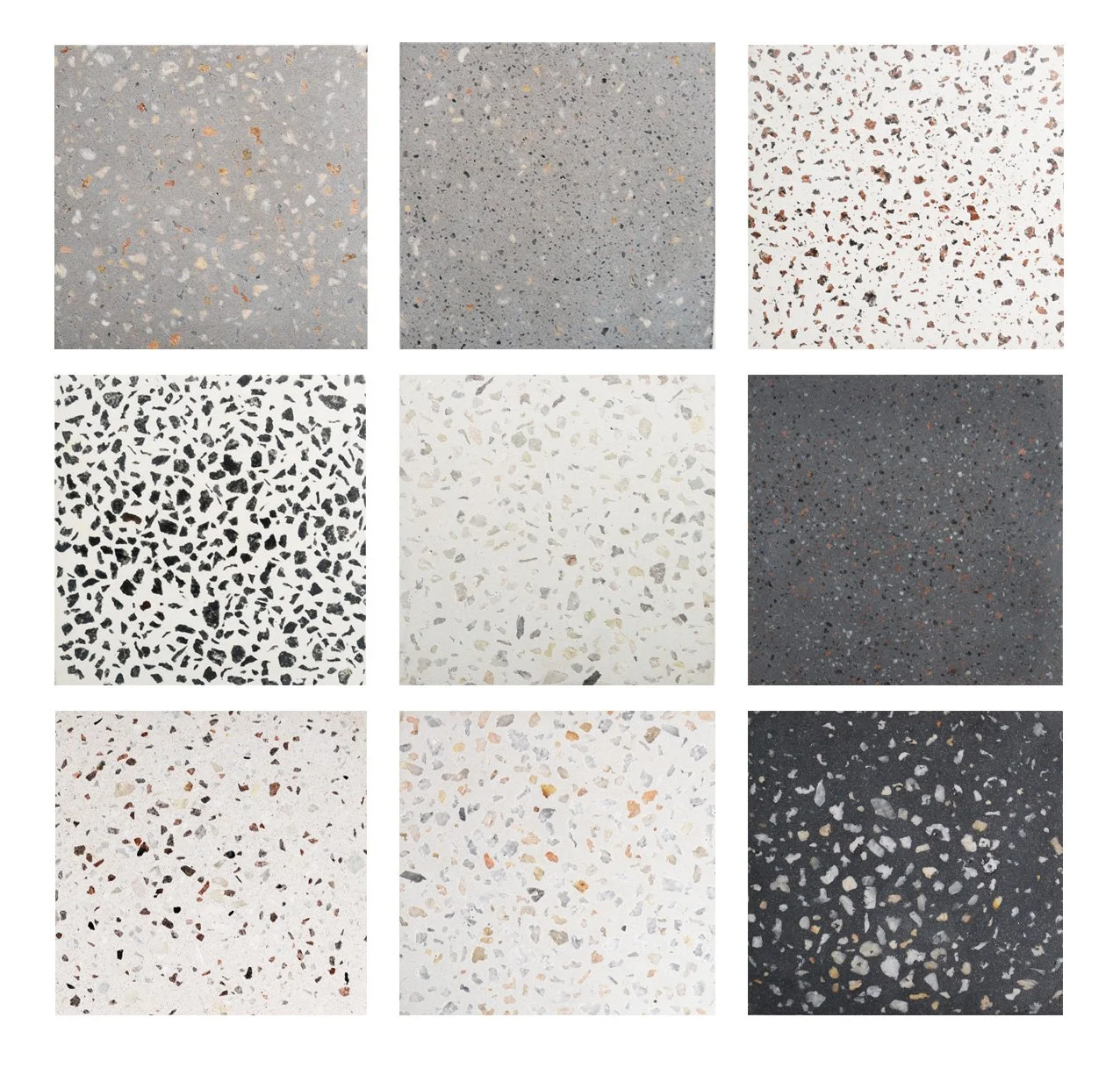

Terrazzo & Granito Finishes

Our basic concrete mix is mostly a mix of cement and fine sand. To this mix we can add different types of crush or aggregates so that we can achieve a terrazzo look. After demolding the piece, the concrete piece is heavily polished with water to expose the aggregates.

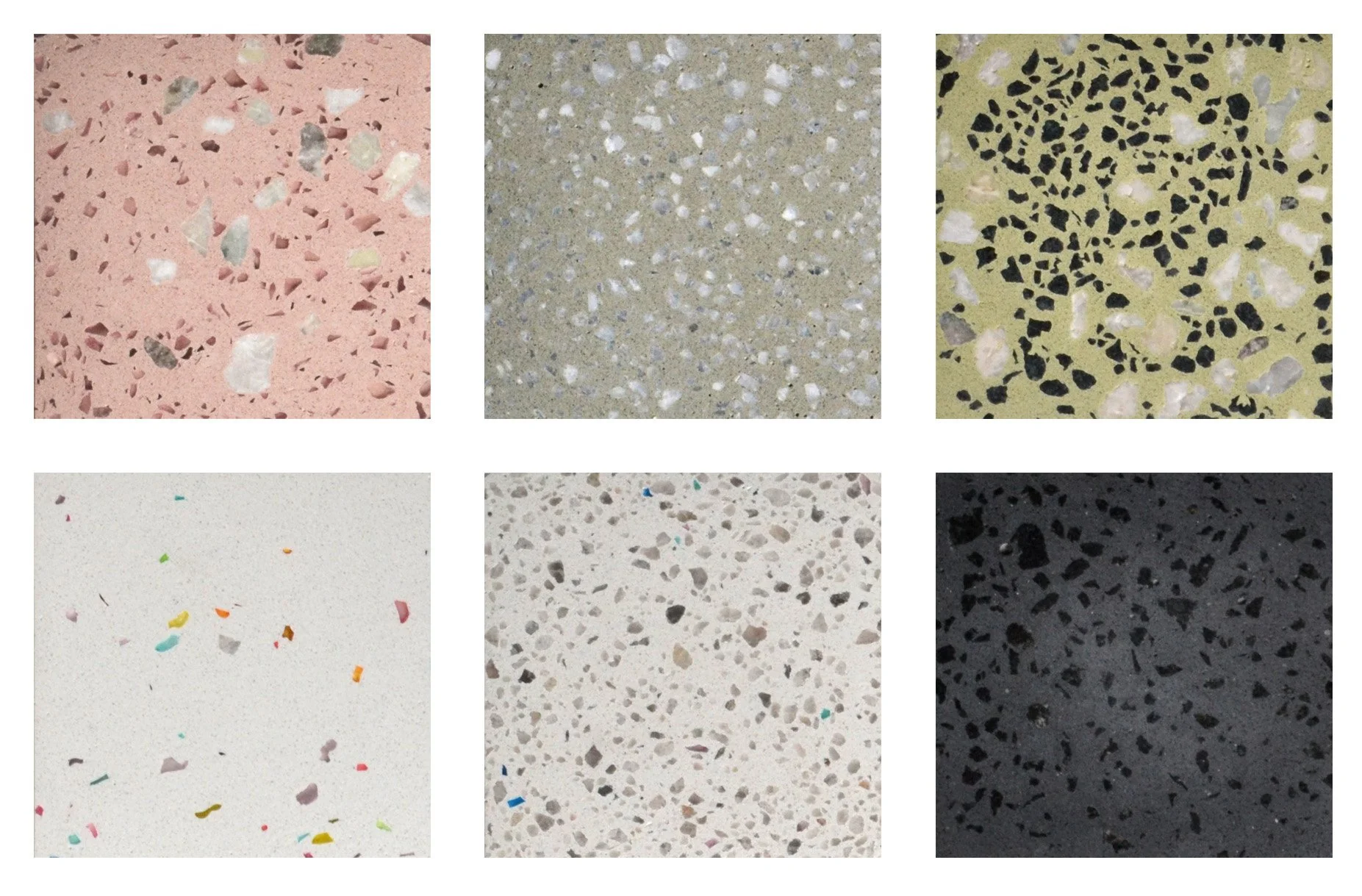

We have a wide selection of aggregates (marble, granite, glass, pebbles,...) in different sizes and colors. We can play with the four main ingredients being: cement, pigment, sand and aggregate. The possibilities are endless and here is a selection of our favourite terrazzo finishes. We mostly produce custom terrazzo mixes so if you have something in mind, drop us a line.

We charge 40€ for a 20/20cm custom terrazzo sample.

Here some samples from our Nature terrazzo collection.

… and some specialty Terrazzo mixes

Wood and metal inlays

It is common to combine or embed different materials in concrete countertops or tabletops.

Edge profile

All edges are either slightly beveled or rounded and we do not leave any sharp edges that may chip easier or be dangerous in household with smaller kids.

As our creations are casted within molds, we can route edgeprofiles with different methods offering fully round edges for different thickness…

Protecting your concrete

Due to its porous properties, all our concrete creations are sealed with a suitable protective coating that will keep your concrete looking great for years to come.

The word great is something that we need to discuss here.

For some of us “great” means “new”. Some of us like the raw and chunky look of concrete. They might also like how patina develops on the surface over time. On the other hand, some of us want a quartz-like, clean cut slim countertop that doesn’t stain at all. Do you keep the kitchen countertop clean at all times? Are you constantly wiping the surfaces? Are you always in a hurry and tend to forget to forget to clean your countertop? These are the things we need to discuss before we start your project.

The market provides a huge amount of protection systems that are each better than the other. We can find:

Topical sealers: in which case you protect your porous concrete with a film of material, which is usually PU (polyurethane). We use topical sealers for most of our creations (tables and countertops) It is very resistant to stains but may scratch easily. Topical sealers keeps your concrete looking new as long as you take good care of it.

Reactive sealers: a chemical reaction with the concrete itself happens and crystals are built within the matrix of the concrete. Reactive sealers protect the concrete in depth giving a more natural look to you countertops.

Waxes: carnauba and bees wax are the most commonly used waxes for concrete. Their protection level is lower than most topical or reactive sealers. On the other hand they are great maintenance and care products for your concrete. Waxes are mostly applied on concrete legs and decorative elements.

Oils: Tung, flax, paraffin oils work very well with concrete. We use oils for eg. on outdoor dinner tables. They are also great maintenance products.

At 16JUIN we work with all the above mentioned products. A kitchen countertop will not be used the same way as a wall panel, therefore it doesn’t need the same protection.

The protection process starts with the preparation of the surface; it is a key phase before applying any sealer.

In the end, remember that there are no material that will last forever. Your concrete piece will age and that is what’s beautiful about this material.

Read more from our care guide.